REFERENCES

Based on 20 years of heat pump R&D, beautiful engineering and more than 40,000 hours of real-world prototype testing, the HoegTemp® holds a competitive edge with its single-lift energy delivery. It is flexible to varying operating conditions and has a fast control response.

References to date include three full-scale steam-generating heat pump projects at IVAR Grødaland, GE HealthCare Lindesnes, and Pelagia Måløy (currently being commissioned).

Standardized & modular unit: easy, containerized installation and automatic operations without the need for major customer-specific adaptations – as opposed to other heat pump systems.

IVAR

BIOGAS PLANT

Our steam generating HoegTemp is replacing the use of fossil gas in the steam boiler reducing the carbon footprint of IVAR. The energy consumption for the CO2 capture in the cooling tower at IVAR is reduced by a factor of 1,8-2, saving up to 50% of energy in that process.

“One of the biggest advantages of the HoegTemp is that the heat pump is retrofittable without major changes to the existing steam supply system. This made it very suitable for the supply of the absorber-stripper system (CO2 removal from biogas) which uses steam at 2 bar pressure,” IVAR engineer, Per Ivar Aarrestad, says.

“Norway and Europe are facing increased electricity prices. This situation favours the use of heat pump technology over the use of electrical boilers. IVAR is therefore considering the use of steam generating heat pumps as a key technology when decarbonising its biogas plants.”

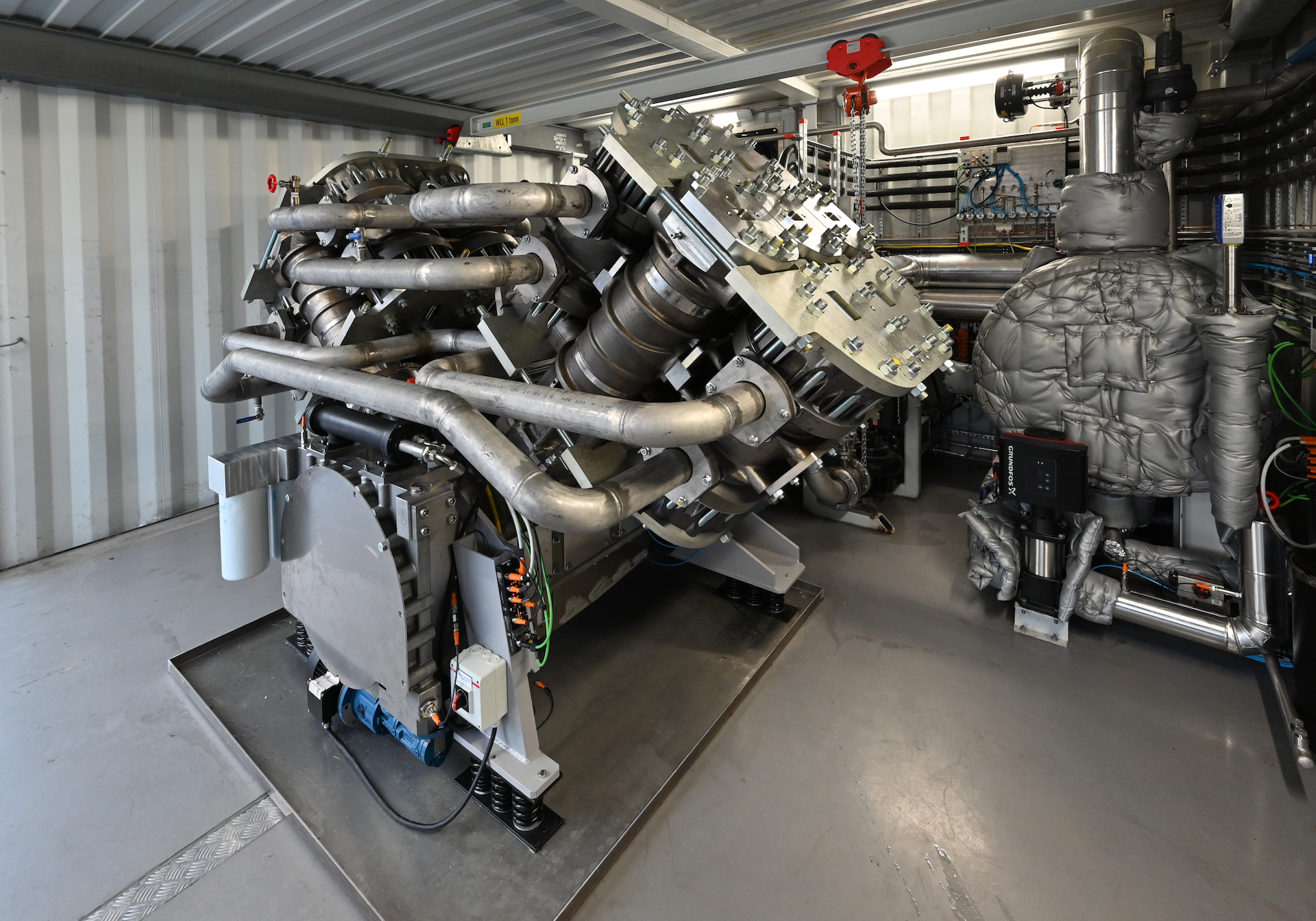

INSTALLATION AT IVAR

BIOGAS PLANT

GE HEALTHCARE

CHEMICAL RECOVERY PROCESSES

Enerin’s HoegTemp high-temperature heat pump is being commissioned at GE Healthcare Lindesnes, Norway.

Enerin’s high temperature heat pump is providing 400kW steam at a temperature of approximately 140°C for the distillation, recovery and reuse of solvents from the production of substances for contrast agents. The delivery of steam pressure varies, depending on the plant’s demand.

GE Healthcare Lindesnes is the leading global manufacturer of substances for X-ray contrast agents used for medical diagnostics.

PELAGIA

FISH PROCESSING

Enerin’s semi-commercial HoegTemp heat pump installation is being implemented at the Pelagia fishmeal factory in Norway for the production of fish oil. It will be used to recover waste heat from Pelagia’s humid air dryers and in condensate streams because the company wants to sever its dependence on fossil fuel boilers.

“The ‘HoegTemp’ seems promising as a reliable and energy-efficient heat pump that is able to deliver process heat with as high a temperature as we require," says Product and Process Developer Ola Flesland at Pelagia AS.

“If a high-temperature heat pump is operated on electricity from renewable energy sources, the CO2-footprint from fishmeal and fish oil production would be reduced to a minimum”, Ola Flesland says.

Contact us

Enerin AS Asker

Torvveien 1

N-1383 Asker

(+47) 92 20 60 59